Swipe Right! What Joint Material Is Your Best Match?

ASTM C144 / C33 sand. Aqua Rock. Joint stabilizing sealers. Polymeric sand. Gator Nitro. Ok, let’s face it … there are a lot of joint material options out there and each one offers a unique set of potential benefits for a hardscape project. In this post, we’re going to outline the factors you should consider when trying to decide which product to use on a job.

Shown here: Gator Nitro Joint Sand

Let’s begin with the basics. With an interlocking concrete paver system, something needs to go in the paver joints to create stability. So what’s interlock and how can it be achieved?

There are 3 main types of interlock

1. HORIZONTAL INTERLOCK

Horizontal interlock refers to resistance to lateral movement. This can be achieved by using an edge restraint system such as the Gator Edge Rigid & Flex or Gator Xtreme Edge.

The friction from the setting bed beneath the pavers also inherently helps with horizontal friction.

2. ROTATIONAL INTERLOCK

Pavers have a tendency to want to twist or roll. This is why rotational interlock is important. Aspect ratios (a.k.a. the general thickness of the paver) need to be taken into consideration. As a rule of thumb, the thicker the paver, the less rotating it will do.

3. VERTICAL INTERLOCK

Vertical interlock is gained by creating friction in between the pavers. (NOTE: Spacer bars do not achieve this! They’re meant, as their name implies, for spacing out pavers only.) A durable joint material (like Gator Maxx G2), however, will do the trick. Not only does the type of joint material matter, but compacting it properly is equally as important. We’ll talk more about this later on.

Now it’s time to learn about the different types of joint materials and why the best-match is application-specific.

Regular Sand

While regular sand will serve the purpose of creating vertical interlock, its major drawback is durability. Regular sand is very susceptible to erosion caused by burrowing insects and weeds, and is therefore not a great solution for professional paver applications.

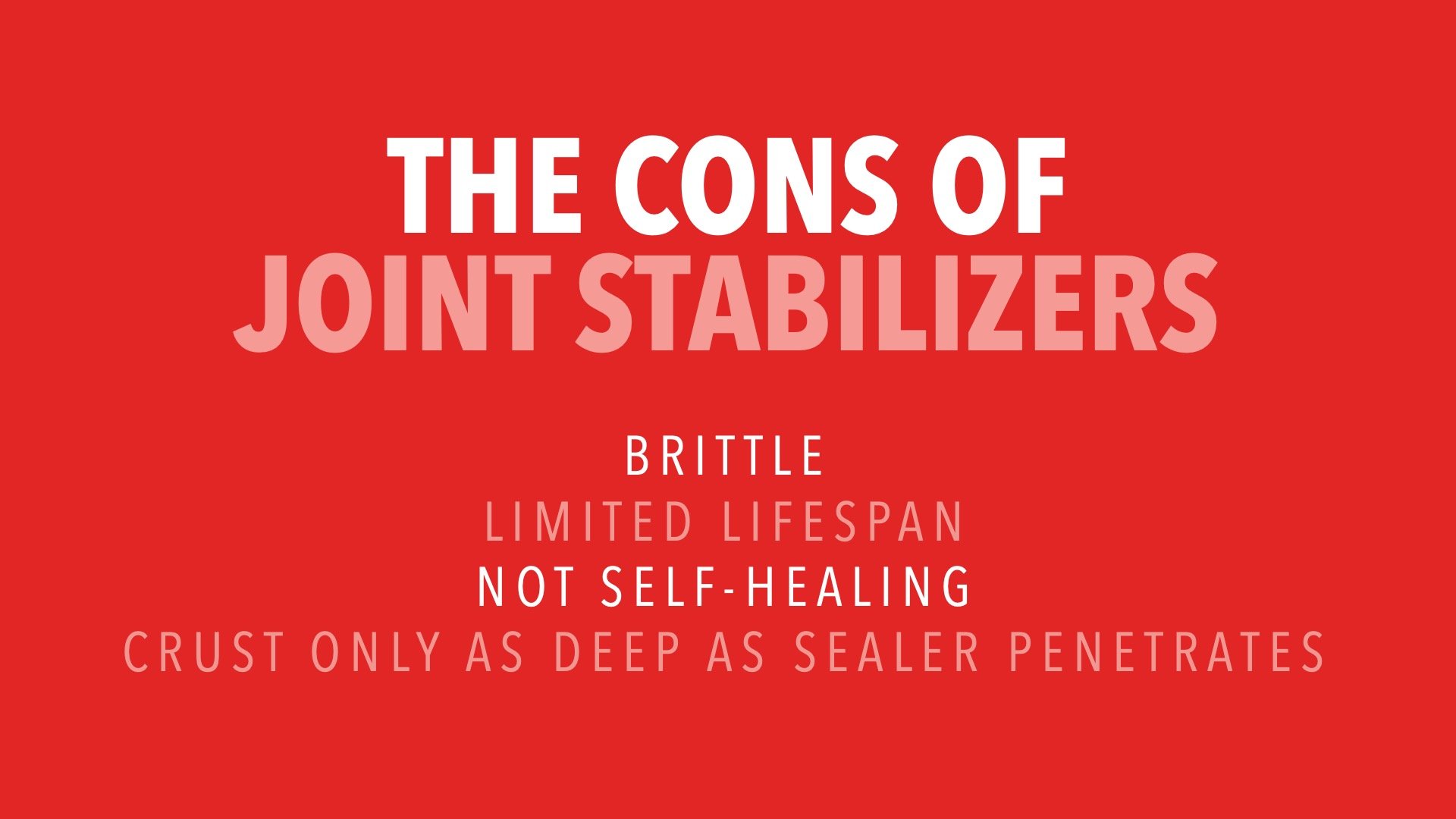

Joint Stabilizing Sealer

The next evolution of joint material was the joint stabilizing sealer. The idea behind this product was to offer a less labor-intense solution for keeping joints looking clean and pristine while still providing the function of interlock.

Joint stabilizers create an extremely rigid joint. However, because of this rigidity, the joints can become prone to cracking. And because joint stabilizers are not self-healing, this issue will not resolve itself once it occurs.

Joint stabilizing sealers will also only stabilize as deep as the sealer itself penetrates when installed. Depending on how densely packed the sand is, what the moisture content is, and how much sealer actually gets applied, the amount of a crust that forms can vary.

Lastly, a joint stabilizing sealer can only be used after the pavers have been given a chance to breathe and release efflorescence. (You should always refer to the paver manufacturer’s recommended wait-time before applying a sealer). Because the product cannot be applied right away, there’s always a chance that the pavers can shift or move before then.

Polymeric Sand

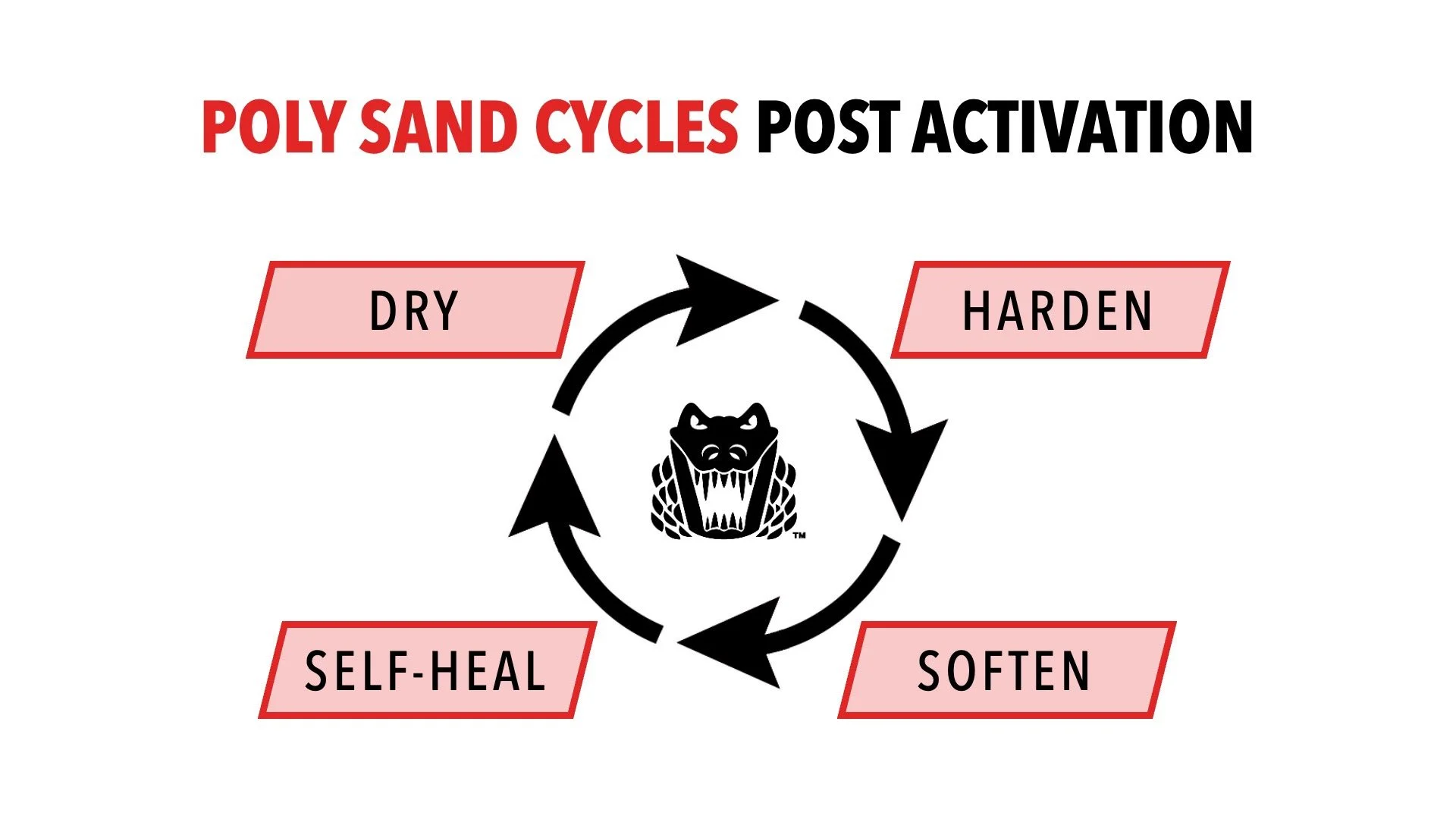

The next best thing that came along after joint stabilizing sealers was polymeric sand. Polymeric sand is a unique blend of polymers and specially calibrated sand that meets specific gradation specs. The product is designed to harden when watered to provide interlock. The polymers, which are also the basic ingredient in plastic, are what gives polymeric sand flexibility. Not only does this product offer superior strength, but the characteristic of flexibility prevents the joints from cracking.

Polymeric sand will withstand the minor movements that a typical paver application will experience over time. The product is designed to go from hard (when dry) to softer (when wet). The process of softening and expanding allows the sand to mesh any cracks and ultimately re-bond together, giving it the unique quality of being self-healing. Polymeric sand can be used in any number of settings, pedestrian and vehicular alike.

Ease-of-use is another big benefit of polymeric sand. When using a product like Alliance’s G2 Supersand or G2 Maxx, the installation process is fairly simple.

Note About Compaction: As we mentioned earlier in this post, compaction is an integral step to a paver installation. Did you know that the sand will be 30-50% stronger when compacted properly? That’s because after an initial compaction, the sand actually drops a significant amount. If you skip the step of compacting and adding more sand, you can be missing up to half the strength within your joints. Water penetration can also become an issue if the sand is not densely compacted.

Hybrid Base

Hybrid or open-graded base has gained popularity in the hardscape industry. It involves either an angular 3/4” clean stone base and a #8 or #9 chip stone setting bed. However, this installation method can pose some challenges when using polymeric sand.

First, let’s take a look at some of the benefits of using the hybrid base method. Drainage is one of the biggest selling points for hybrid base, as there won’t be any moisture problems to contend with (given there’s a way for the water to properly escape). A free-draining application can also help decrease the amount of efflorescence in pavers.

The hybrid base method also allows you to work a little bit longer into the season. You’re not going to have a pile of aggregate that can potentially start to freeze on the job site and you can work in more wet conditions as well.

The main issue with using a hybrid base is that the joint sand can actually drop down into the sub-grade depending on how large the gaps are in between the aggregate used. With that said, polymeric sand can certainly be used on a hybrid base installation. You’ll just want to ensure that you’re using the right type of aggregate!

Pea gravel is round so it’s definitely not a good choice for a hybrid base. You always want to use something angular that can lock/pack together. Consider using an aggregate that has varied shapes and sizes, like a #9 stone. The pieces of aggregate will bond and mesh together more tightly, which will help decrease the gap sizes between each piece. The choking out of the aggregate not only provides a more solid base, but it also helps alleviate the joint sand from being able to drop down into it.

The key to successfully using polymeric sand on a hybrid base is two-fold. You must use the right type of aggregate and you must compact that sand until it chokes itself off and does not migrate down into the sub-base (again, #9 stone will be the best option).

Gator Nitro

Gator Nitro is Alliance’s newest resin-based product. First off, it doesn’t require any compaction (although you still need to pre-compact your pavers). While poly sands form a thick and durable crust, Nitro provides top-to-bottom strength within the joint. This product gets incredibly hard. With that said, the joints won’t have any flexibility and could be prone to cracking. Another big benefit of Nitro: it can be installed rain or shine. Because the installation process involves so much water, installing it in the rain is a good thing! It’s also a great consideration for a hybrid base application.

In closing

If this was a dating app, we’ll assume by now you’ve done some swiping! Choosing a joint material is easy as long as you understand the features of the product. There’s no one-size-fits-all sand.

Have a little more time? Be sure to watch our on-demand training broadcast, Polymeric Sand vs. Gator Nitro. In this session, our Technical Support Team does a deep dive on the major differences between these two products and the best applications for each.