How much polymeric sand is needed to fill a paver joint?

Over- or under-filling paver joints with polymeric sand can lead to project failures. In this blog post, we’ll explain how much sand is needed to sufficiently fill the joints and the steps on how to do it.

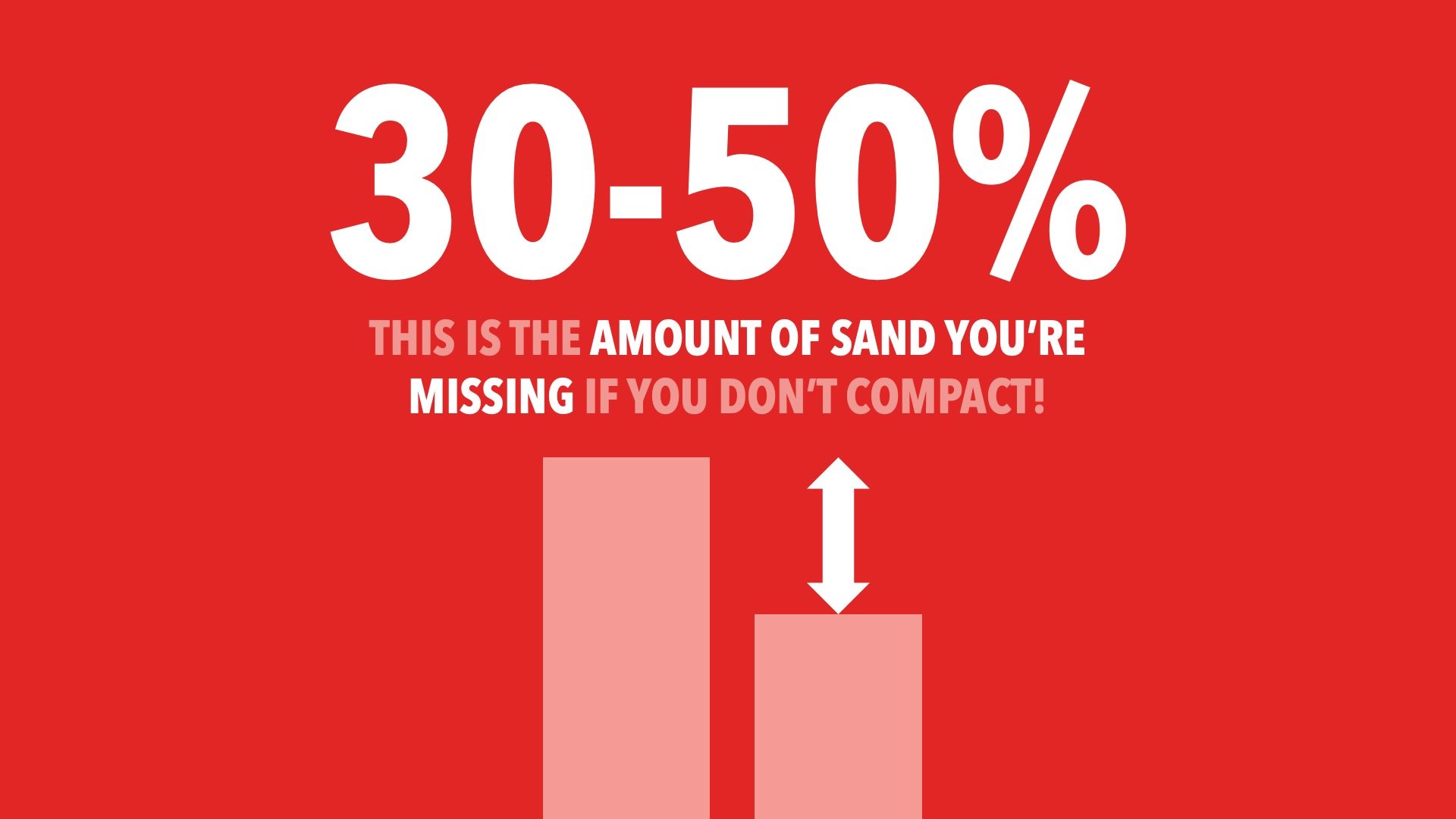

One of the most important steps in a polymeric sand installation is proper compaction of the sand into the joints. Ideally this is done using a vibratory plate compactor. After the initial compaction, you’ll notice that the height of the sand will drop dramatically down into the joint, about 30-50%! This is why it’s important to sweep in more sand to ensure the joints get filled up to 1/8 in. below the paver's edge or chamfer.

The best way to fill paver joints with polymeric sand is to start by spreading the sand across the surface using a hard-bristle broom. During this phase, you’ll want to make sure the sand completely fills the joints. It’s important to note that you should be working with clean joints. If there’s any residual material in between the joints, you’ll have to completely remove it before getting started. You never want to mix different materials within the joints. As you’re sweeping, leave a layer of sand on the surface to aid in the vibrating and consolidation of the product into the joints.

Never mix different materials within a joint.

The next step is vibrating the sand into the paver joints using a vibratory plate compactor. We recommend using a rubber pad to protect the paver surface. A roller compactor is best to use for slab installations.

The joints should be filled up to 1/8 in. below the paver’s edge or chamfer. It’s best to compact in several directions to ensure there are no air gaps or voids in the joints. You’ll want to repeat sweeping and compacting until the joints are filled and consolidated. Keep in mind, narrow joints require more care to completely fill.

A common mistake we see during the final sweeping of excess polymeric sand from the surface is using too much force. Sweeping too aggressively can push sand out of the joints, leaving too little product to set up properly. When sweeping excess product from the surface, we recommend doing a first pass with a hard-bristle broom, then going back with a soft-bristle broom. Again, take care to leave the height of the polymeric sand at least 1/8 in. below the edge or chamfer of the paver.

Recap

Achieving the proper height of polymeric sand within the paver joint will be critical to the overall success of the project. The sand should only be filled to about an 1/8 in. below the chamfer of the paver. Be sure a proper compaction is performed after initially sweeping the sand in. Remember, about 30-50% of the sand will drop after compacting and more sand will have to be added. Do not fill the sand up to or above the top of the paver and never mix materials within the joints. Follow these simple rules to sufficiently fill your paver joints and get the most out of your polymeric sand.

To learn more about polymeric sand and how to properly install it, be sure to take our free Polymeric Sand For Dummies training on-demand!